Throughout my 20-plus years in pavement management, I’ve rated many thousands of miles of municipal roads, managed over a hundred pavement condition surveys, implemented many lifecycle models, and seen the results of countless pavement management strategies. While there is no one-size-fits-all solution, a combination of an accurate pavement condition survey, lifecycle modeling, and pavement preservation treatments can help communities efficiently maintain their roadway assets.

We all know these roads don’t last forever but through effective management, we can significantly cut the cost of ownership. Many municipalities prioritize streets that are in the worst shape. This approach leads to the lowest level of service for the highest cost— also known as a worst-first approach. The entire pavement budget is spent on a handful of roadway segments, leaving the other streets untreated. Eventually, these end up requiring total reconstruction, making it very difficult to catch up.

There is a better way, though. Using lifecycle modeling and preservation treatments, municipalities are finding that they can keep the roadway network at a higher level of services for a lot less cost. Managing “perpetual pavements” is the goal. This term is explained below.

Perpetual pavement

In the past, many municipalities have accepted the fact that pavement would ultimately reach the end of its useful life, fail, and require full-depth reconstruction. With a worst-first approach, this is true and extremely expensive. By using the preservation treatments mentioned above, a municipality can S-T-R-E-T-C-H the life of the asphalt riding surface and protect the pavement base. Our experience has shown that typical untreated pavement will last on average about 17 years. When multiple rounds of pavement preservation treatments are applied, this same pavement can last up to 30 years. At some point, the asphalt riding surface will have to be milled up and replaced, but we have protected the base and will only need to make minor base repairs versus wholesale base replacement. This saves money. Protecting the base at all costs is critical, and this is better known in the industry as perpetual pavement.

First things first: Pavement condition survey

However, at the core of a successful pavement management program and lifecycle modeling is a comprehensive pavement condition survey (PCS). This is a procedure that involves regular inspections to understand the current condition of the pavement. Through accurate and consistent pavement condition ratings, you can anticipate upcoming maintenance needs, allowing for planned, budgeted maintenance instead of costly, reactionary repairs. While there are many PCS standards (ITRE, LTPP, ASTM, PASER, etc.) and methods for data collection (visual, artificial intelligence (AI), automated, & hybrid), the key is to select the standard and method that provides the data needed to make the best decisions to manage your roadway network and possibly other assets. Holding a planning meeting to assess these needs at the beginning will go a long way in selecting the right rating standard and methodology.

Once the PCS is complete, it’s important that we leverage this data through lifecycle modeling so all stakeholders can make timely cost-effective pavement management decisions. Understanding and planning for the lifecycle of pavement is key to budget-conscious road management. A lifecycle model is a tool that allows us to predict future roadway network conditions based on deterioration models, numerous funding levels, and different treatment types. Another substantial benefit is being able to generate optimized yearly work plans that select the best projects across multiple maintenance activity categories based on an optimal return on investment. Lifecycle model optimization selects the combination of treatments each year that will provide the most benefit (improved condition) for the budget over the entire network. This is known as “selecting the right mix of fixes.”

Lifecycle modeling paints a clear picture

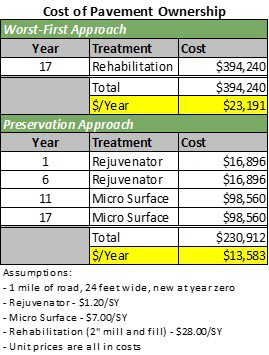

With a lifecycle model, demonstrating the cost benefits of a preservation approach, which tends to be less understood, versus the familiar worst-first approach is easily and clearly accomplished in terms that are easy to understand. In the table, Cost of Pavement Ownership, a similar comparison is provided that also demonstrates the cost-to-benefit of using a preservation approach.

With a lifecycle model, demonstrating the cost benefits of a preservation approach, which tends to be less understood, versus the familiar worst-first approach is easily and clearly accomplished in terms that are easy to understand. In the table, Cost of Pavement Ownership, a similar comparison is provided that also demonstrates the cost-to-benefit of using a preservation approach.

Lifecycle modeling also tells the story of your roadway network. If you have been underfunded for years, it becomes possible to demonstrate to the elected officials the consequences of underfunding and what is needed to reach a determined level of service (pavement condition index) over time. In many cases, this awareness can lead to increased funding.

Preventive treatments for a longer life

Preventive preservation treatments have evolved significantly over the years, offering efficient alternatives to traditional pavement repair. These treatments are designed to preserve and extend the life of the pavement while being significantly less expensive than traditional repair or replacement. Methods such as rejuvenation, crack sealing, and micro surfacing can address minor pavement distresses before they develop into more significant problems.

Rejuvenators, when applied to newly paved streets (typically 1 to 4 years old), will preserve the plasticity and durability of the asphalt which will effectively extend the life of the pavement by restoring components of the liquid asphalt. Crack Seal, which is a rubberized asphalt material, is applied to environmental cracks to keep surface water from getting into the base, which over time can create base failures. Micro-surfacing is a mixture of polymer-modified emulsified asphalt, crushed aggregate, water, and other additives, properly proportioned that can correct minor rutting and improve and protect the road surface quality.

What about asphalt overlays and paving into the gutter? Don’t do it. These are only stop-gap measures. Existing crack patterns will come back after a short period of time and as successive overlays are performed, we create drainage problems, ADA compliance issues, and eventually end up paving to the top of the curb. Milling at this point adds significant cost to the yearly resurfacing program which leads to paving fewer streets, further contributing to the decline of the overall roadway network condition. This approach amounts to just kicking the can down the road. Or, as the U.S. Federal Highway Administration (FHWA) put it in a recent report: “Today’s users are, in effect, consuming the infrastructure of their children.”

Using the mentioned preservation treatments in an appropriate sequence can effectively manage the pavement’s lifecycle and maximize the service years from the initial investment. By implementing FHWA’s 3Rs (resurfacing, restoration, and rehabilitation), a municipality can significantly reduce lifecycle costs and develop a foundation for a budget-conscious pavement management plan.

In conclusion, balancing a limited budget with the need to maintain the community’s pavement assets is a challenge. However, with careful lifecycle modeling, adherence to pavement management best practices, and an understanding of the latest preservation treatments, communities can extend the life of their pavements, save money, and provide safer, smoother roads for their residents. Remember, an ounce of prevention is worth a pound of cure, especially when it comes to managing your roadway networks.

If you have more questions about pavement management or a project, reach out to Director of Pavement Management Steve Lander at (919) 238-0380 or slander@withersravenel.com .